FRP Moulded Grating Provider

Table of Contents

Introduction

AQUALID is a leading manufacturer of high-quality FRP (Fiber Reinforced Plastic) and GRP (Glass Reinforced Plastic) manhole covers, designed for durability, strength, and safety. With a commitment to innovation and sustainability, AQUALID provides lightweight, corrosion-resistant, and high-load-bearing solutions for various industries, including municipal, commercial, and industrial applications. Our products are engineered to withstand harsh environments, ensuring long-lasting performance without rusting, breaking, or theft risks. We offer a wide range of customizable designs to meet the specific needs of roads, drainage systems, telecom networks, and water treatment plants.

Choosing the appropriate materials is crucial for cost-effectiveness, durability, and safety in the fast-paced industrial environment of today. Although traditional materials like concrete, steel, and wood have long been used, they frequently have drawbacks, particularly in harsh locations. Presenting FRP Moulded Grating, a revolutionary option that is quickly taking the lead in numerous industries.

Everything you need to know about FRP molded grating, including its amazing advantages, wide range of uses, and why it’s a better option than traditional materials, will be covered in this article. And as a top supplier of FRP moulded grating, AQUALID is here to demonstrate how our dedication to excellence, creativity, and client satisfaction makes us the perfect partner for all of your grating requirements. We are the best FRP Moulded Grating Manufacturer.

What Exactly is FRP Moulded Grating

Fiberglass Reinforced Plastic is referred to as FRP. Imagine glass fibers that are extraordinarily durable being woven together and then soaked in a unique liquid glue. The result is FRP moulded grating after this mixture is “moulded” into a grid-like panel and allowed to cure. The one, integrated item produced by this special manufacturing method has remarkable strength in all directions.Because molded grating is interlaced, its total strength isn’t greatly affected even if a part is cut out for pipes or equipment, unlike pultruded FRP grating, which has unidirectional strength. Because of this, it is highly flexible and can be adjusted to meet different design needs. We are the best FRP Moulded Grating Supplier.

Why Choose AQUALID

AQUALID is not just a manufacturer; we are innovators committed to delivering cutting-edge FRP solutions that redefine reliability and performance. Established in 2019, we have quickly become a trusted name in the industry, specializing in a wide range of high-quality FRP products, including FRP Manhole Covers, FRP Gully Covers, and of course, premium FRP Moulded Grating.

- Unwavering Quality Assurance: Quality is the foundation of all we do at AQUALID. Throughout our manufacturing process, we comply with the most stringent international quality standards To make sure that every FRP moulded grating panel that leaves our facility is constructed to withstand the harshest conditions and provide long-lasting performance, we only use premium fiberglass reinforcements and the best resins, such as isophthalic polyester and vinyl ester, which are renowned for their exceptional corrosion resistance. We strive to surpass standards rather than merely meet them.

- Experience and Expertise: Our team is made up of technical experts and talented engineers with extensive industry knowledge. From material selection to installation, we can offer expert advice because we comprehend the subtleties of different industrial applications. Our history of successful projects in a variety of industries, including construction, power plants, chemical industries, and oil and gas, speaks eloquently about our abilities and dedication.

- Customization to Meet Your Needs: We think that offering solutions, not just goods, is important. AQUALID provides a wide range of customisation choices to satisfy your unique project needs. We can customize our FRP moulded grating to meet your exact requirements, whether you have certain panel sizes, thicknesses, mesh patterns, colours, or even specialised resin systems for harsh chemical exposures. We are able to provide precisely engineered items thanks to our cutting-edge production facilities and sophisticated manufacturing techniques.

- Sustainability Commitment: AQUALID is committed to creating a better future. We are committed to providing environmentally friendly solutions. Our FRP products are made to last, which minimizes their impact on the environment and lessens the need for regular replacements. In keeping with our dedication to a greener future, we consistently invest in cutting-edge technology and research to create energy-efficient production methods and employ sustainable materials.

- Customer-focused strategy: Our greatest accomplishment is your contentment. Throughout the project lifetime, we place a high value on open and honest communication while providing easily accessible technical support, installation instructions, and troubleshooting help. Our goal is to ensure a smooth and effective project experience throughout. Our happy customers praise our exceptional quality, prompt delivery, and first-rate customer care, so don’t just take our word for it.

- Innovation at the Heart: To provide you with the newest developments in FRP technology, we are continuously investing in research and development. This guarantees that our goods are ready for the challenges of the future in addition to fulfilling the criteria set by the industry today.

Applications of FRP Moulded Grating

- FRP really excels in chemical processing plants. Conventional materials would be rapidly degraded by exposure to highly corrosive acids, alkalis, and other chemicals. In order to maintain operational continuity and worker safety, AQUALID FRP moulded grating offers sturdy, long-lasting platforms, walkways, and trench covers that are resistant to chemical attack.

- Water and Wastewater Treatment Plants: These settings are quite difficult because to the continuous exposure to damp, chemicals, and microbial development. With their exceptional corrosion resistance and low maintenance requirements, AQUALID FRP gratings are ideal for filter platforms, tank lids, drainage channels, and walkways.

- Oil and Gas Industry: The oil and gas industry works in some of the most dangerous and corrosive settings, from refineries to offshore platforms. For walkways, stair treads, and platforms, AQUALID FRP gratings offer strong, non-slip surfaces that improve safety and lower maintenance costs in these crucial installations.

- Power Plants: AQUALID FRP gratings’ non-conductive nature and corrosion resistance are crucial due to the existence of electrical risks and frequently corrosive wastes. They guarantee a safer working environment and are frequently utilized for flooring, control rooms, battery areas, and access platforms.

- In the food and beverage industry, cleanliness is crucial. AQUALID FRP gratings are perfect for processing areas, bottling lines, breweries, and dairies where cleanliness is crucial because they are simple to clean, resistant to cleaning agents, and non-corrosive.

- Marine and Offshore Environments: Metal deteriorates quickly in saltwater and severe weather. Because they don’t corrode in seawater, AQUALID FRP gratings are ideal for ship decks, docks, marinas, jetties, and other marine structures.

- The lightweight nature, high strength, and resistance to environmental factors of AQUALID FRP gratings make them a preferred choice for modern construction projects, lowering installation time and long-term maintenance requirements for everything from bridges and maintenance platforms to stair treads and trench covers.

- Materials that can endure harsh environments, large loads, and abrasive chemicals are needed by the mining and metals sectors. In these difficult settings, AQUALID FRP grating provides a strong, corrosion-resistant, and high-strength option for platforms, screening, and walkways.

Specification Table of FRP Moulded Grating

| Property | Specification |

|---|---|

| Material | FRP Moulded Grating |

| Manufacturing Method | Moulded |

| Panel Size | 1220mm x 3660mm / 1000mm x 3000mm (Custom sizes available) |

| Mesh Size | 25mm x 25mm / 38mm x 38mm / 50mm x 50mm |

| Thickness | 25mm / 30mm / 38mm / 50mm |

| Load Capacity | Up to 5 tons depending on panel thickness |

| Surface Options | Gritted / Concave / Plain |

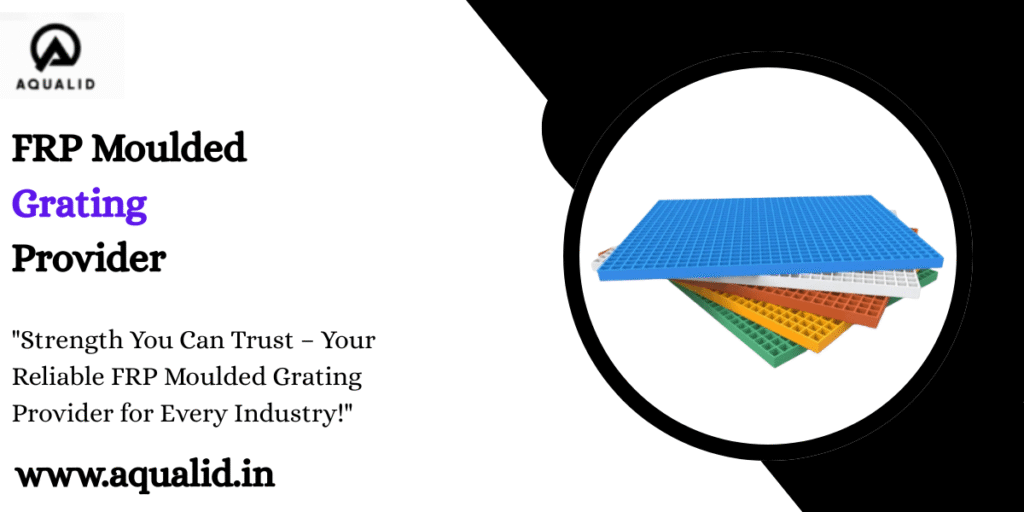

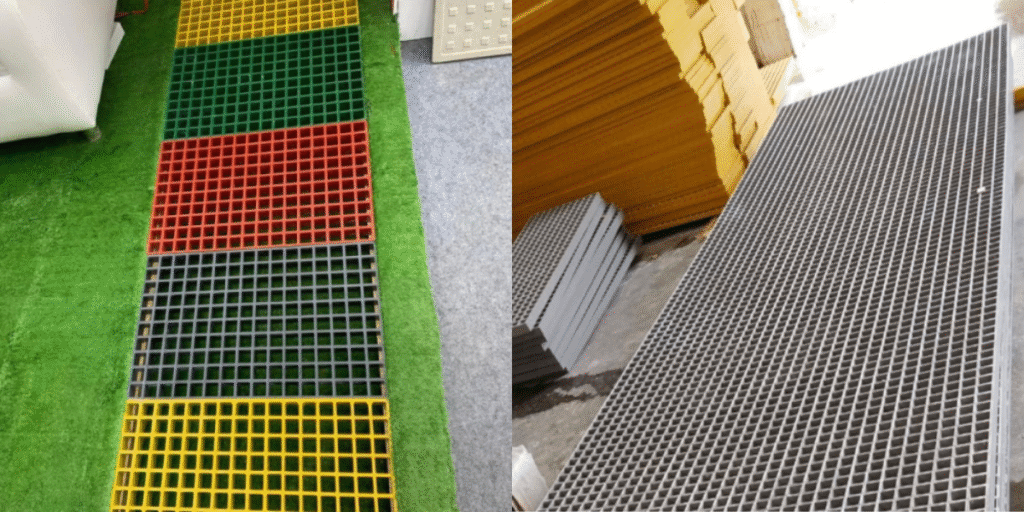

| Colour Options | Grey, Green, Yellow, Blue (Customizable) |

| Fire Retardant Grade | ASTM E84 Class 1 Available |

| UV Protection | Yes |

| Conductivity | Non-Conductive |

| Corrosion Resistance | Excellent |

| Installation | Clamp & Fixing Accessories Available |

Advantages of FRP Moulded Grating

- Perhaps the most important advantage is superior corrosion resistance. FRP is essentially impervious by rust and corrosion, unlike steel, which is susceptible to these conditions in severe settings (think chemical spills, saltwater, or continual dampness). Because of this, it is the best option for sectors that deal with corrosive materials, thus increasing the longevity of infrastructure and lowering replacement costs.

- High Strength-to-Weight Ratio: Fiber Reinforced Polymer (FRP) moulded grating has an amazing strength-to-weight ratio, even though it is extremely lightweight (often 70% lighter than steel!). This implies that it is significantly easier to handle, install, and transport while yet being able to support large loads. Weight reduction results in significant cost savings and quicker project completion since it reduces transportation costs, requires less taxing manual work, and frequently eliminates the need for heavy lifting equipment during installation.

- Outstanding Longevity and Durability: FRP is made to last. It is resistant to environmental elements like UV rays, collision, wear and tear, and fatigue. Because of their intrinsic resilience, they have a far longer service life than traditional materials, which results in fewer replacements and repairs and lower lifetime costs overall.

- Safe and Non-Conductive: One important safety aspect in areas with electrical risks is that FRP is electrically non-conductive. This makes it perfect for power plants, substations, and other electrical facilities since it removes the possibility of electrical shocks. Additionally, FRP moulded grating can be produced with a gritty, non-slip surface that offers exceptional traction even in cold, wet, or oily conditions, thus lowering the chance of slips and falls.

- Low Maintenance: Bid farewell to painting, removing rust, and ongoing maintenance! FRP-molded grating needs very little upkeep. It is impervious to decay, rust, and vermin. It can typically be kept clean and working with just a basic high-pressure wash, which further reduces long-term costs.

- Fire Retardant Properties: To meet strict safety regulations and provide an extra degree of security in industrial environments where fire threats may exist, many FRP moulded gratings are designed with fire-retardant additives.

- Flexibility and Customization: FRP moulded grating is available in a range of thicknesses, mesh sizes, panel sizes, and even colors. Whether it’s for heavy-duty platforms, pedestrian walkways, or unique drainage systems, this adaptability enables highly customized solutions to meet project needs. Its versatility on-site is further increased by its ease of cutting with common hand tools.

Types of FRP Moulded Gratings

1. Square Mesh FRP Moulded Grating

- Most commonly used

- Equal load distribution

- Ideal for walkways, platforms, and general use

2. Rectangular Mesh FRP Grating

- Used where direction-specific strength is required

- Suitable for drainage areas, trench covers, and industrial flooring

3. Mini Mesh FRP Grating

- Smaller openings for pedestrian traffic

- Prevents small objects from falling through

- Suitable for public walkways, swimming pool areas

4. Heavy Duty FRP Moulded Grating

- Extra-thick for heavy load-bearing

- Ideal for vehicle movement areas, factories, and airports

5. Covered FRP Gratings (with Chequered Plates)

- Flat surface with anti-slip properties

- Used for food processing units, hospitals, or cleanroom areas

Conclusion

For any industrial or commercial setting, FRP moulded grating is more than simply a material; it’s a wise investment in longevity, safety, and efficiency. It clearly outperforms conventional materials due to its unmatched corrosion resistance, high strength-to-weight ratio, excellent safety features, and low maintenance needs. We are the best Best FRP Moulded Grating Provider.

Consider the many benefits of FRP molded grating when you’re thinking about expanding your projects or improving your infrastructure. And AQUALID is prepared to be your reliable partner when it comes to selecting a supplier that offers quality, personalization, and steadfast customer service. Discover the AQUALID distinction, where safety is long-lasting and innovation meets dependability.