FRP Gully Cover in West Bengal

Table of Contents

Introduction

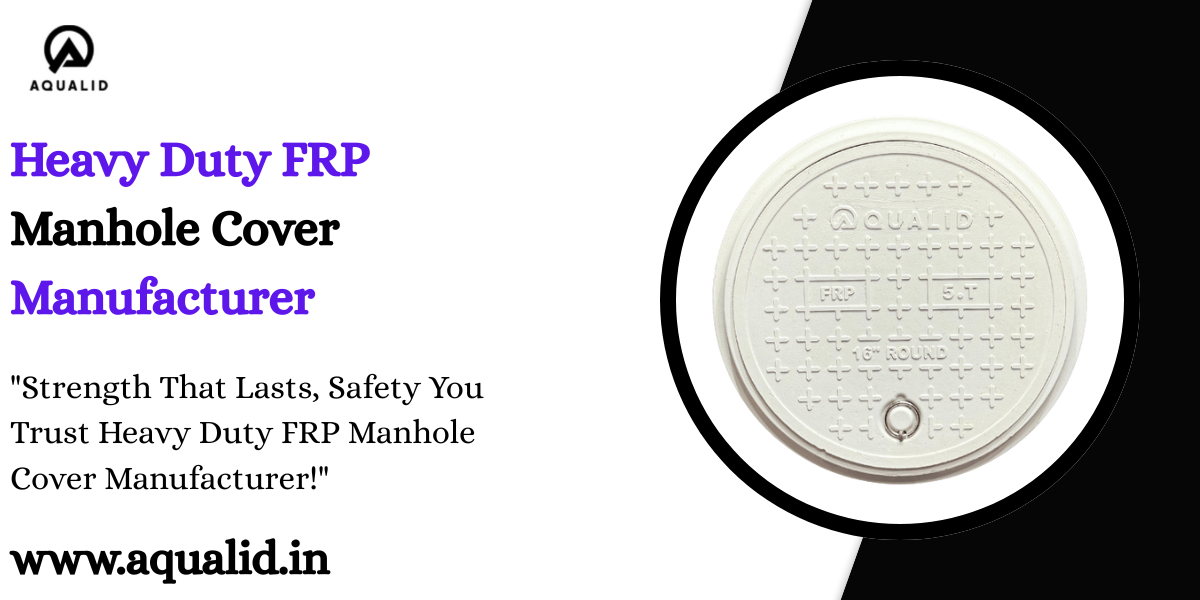

AQUALID is a leading manufacturer of high-quality FRP (Fiber Reinforced Plastic) and GRP (Glass Reinforced Plastic) manhole covers, designed for durability, strength, and safety. With a commitment to innovation and sustainability, AQUALID provides lightweight, corrosion-resistant, and high-load-bearing solutions for various industries, including municipal, commercial, and industrial applications. Our products are engineered to withstand harsh environments, ensuring long-lasting performance without rusting, breaking, or theft risks. We offer a wide range of customizable designs to meet the specific needs of roads, drainage systems, telecom networks, and water treatment plants.

It is impossible to overestimate the significance of robust and effective infrastructure in the busy environments of contemporary urban development. The fundamental structure of a city determines its operation and the standard of living for its residents, from efficient drainage systems to easy traffic flow. Gully coverings are often disregarded, although they are vital. We are the best FRP Gully Cover Manufacturer.

These ostensibly straightforward elements are essential to maintaining our urban settings’ longevity, safety, and hygienic conditions.The topic of gully covers is explored in this essay, with a particular emphasis on Fiber Reinforced Polymer (FRP) as an excellent material option. The advantages of FRP gully covers will be discussed, as well as how AQUALID, a top supplier of cutting-edge infrastructure solutions, is positioned to satisfy the rising demand for these necessary goods in places like West Bengal, India, and the United Arab Emirates (UAE).

Understanding the FRP Gully Cover

It’s critical to comprehend the significance of gully covers before delving into the finer points of FRP. Gullies, sometimes referred to as catch basins or drainage inlets, are holes in the earth or pavement that let surface runoff and precipitation enter the subterranean drainage system. Gully coverings fulfill a number of vital purposes: We are the best FRP Gully Cover Supplier.

Why Choose AQUALID

Gully coverings are among the premium Fiber Reinforced Polymer (FRP) products that AQUALID is a top supplier of in the United Arab Emirates. We are dedicated to providing our clients with creative, long-lasting, and reasonably priced solutions that satisfy their various needs. The following justifies choosing AQUALID as your go-to partner for FRP gully covers:

- Unwavering Quality: To create FRP gully covers that satisfy the highest requirements for strength, durability, and corrosion resistance, we use premium-grade raw materials and cutting-edge manufacturing techniques. Our goods are made to last, guaranteeing their value and performance throughout time.

- Tailored Solutions: We understand that every project has different needs. A large variety of FRP gully cover designs, sizes, and load-bearing capacities are available from AQUALID. We also provide customisation choices, such as branding and specialty features, to satisfy particular functional or aesthetic requirements.

- Lightweight and Easy to Handle: Compared to conventional options, our FRP gully covers are substantially lighter, which facilitates easier and safer installation, maintenance, and transportation all of which ultimately save labor costs and project schedules.

- Superior Corrosion Resistance: Our FRP materials are designed to endure the severe environmental factors that are common in West Bengal and the United Arab Emirates, such as high salinity, humidity, exposure to chemicals, and extremely high temperatures. This guarantees low maintenance and a long service life.

- Improved Safety Features: Safety comes first. To stop slips and falls, AQUALID FRP gully covers can be made with non-slip surfaces. Additionally, the fact that they are lightweight lowers the possibility of handling injuries. They also add an extra degree of security in locations with electrical installations because they are non-conductive.

- Cost-Effective in the Long Run: FRP gully covers may initially cost the same as or slightly more than traditional options, but over time, their long lifespan, minimal maintenance needs, and lower replacement costs make them a far more economical choice.

- Stylish Designs: To guarantee that our gully covers blend in perfectly with the surrounding urban environment, we provide a range of styles and color choices. Options for customization provide customized looks to fit particular project specifications.

- Environmentally Friendly: Compared to traditional materials, FRP manufacture frequently uses less energy. A more sustainable infrastructure solution is also facilitated by the lengthy lifespan and decreased need for replacement.

- Proven Performance History: AQUALID has a developing history of providing premium FRP gully covers for a range of projects in the UAE and India. Because of our dependable products and dedication to quality, our clients have faith in us.

Advantages of FRP Gully Cover

- High Strength-to-Weight Ratio: FRP has an exceptionally high strength to weight ratio. This indicates that FRP gully covers are substantially lighter than their cast iron or concrete counterparts and can support severe loads, including traffic. Because they are lightweight, handling, transporting, and installing them is simpler, which lowers labor expenses and the risk of accidents.

- Corrosion Resistance: Metal-based infrastructure is seriously threatened by the UAE’s environment, which includes high humidity, salty air, and sporadic chemical exposure in industrial locations. Gully covers made of cast iron are susceptible to rust and corrosion, which can weaken them, cause structural collapse, and necessitate regular repair. In contrast, FRP is naturally impervious to corrosion caused by a variety of chemicals, moisture, and salt. This significantly increases the FRP gully cover’s lifespan and lowers the need for ongoing maintenance and replacement.

- Long Lifespan and Durability: FRP materials are renowned for their remarkable resilience to impact, weathering, and UV rays. They can endure the severe weather in the United Arab Emirates for an extended period of time, keeping their structural soundness and aesthetic appeal. In the long term, FRP gully covers are a cost-effective alternative since they have a longer service life than traditional materials.

- Non-Conductivity: Fiber Reinforced Polymer (FRP) is a superior electrical insulator. This is a major safety benefit, particularly near drainage systems where there may be electrical cables or other electrical hazards. By removing the possibility of electrical conductivity, FRP gully covers protect both maintenance workers and pedestrians.

- Design freedom: Compared to conventional materials, FRP offers more design freedom because it can be molded into a variety of shapes and sizes. This makes it possible to create visually appealing gully covers that can be tailored to meet the needs of particular projects. FRP designs can also readily incorporate features like integrated locking mechanisms and non-slip surfaces.

- Low Maintenance: FRP gully covers require less upkeep because of their longevity and resistance to corrosion. They save time and money because they don’t require painting or frequent anti-rust treatments. Usually, regular cleaning to get rid of debris is enough to keep them working well.

- Environmental Benefits: When compared to the production of cast iron, FRP manufacturing frequently uses less energy. Additionally, because FRP gully covers last a long time, fewer replacements are required, which minimizes trash production. The environmental sustainability of certain FRP materials is further improved by the use of recycled components.

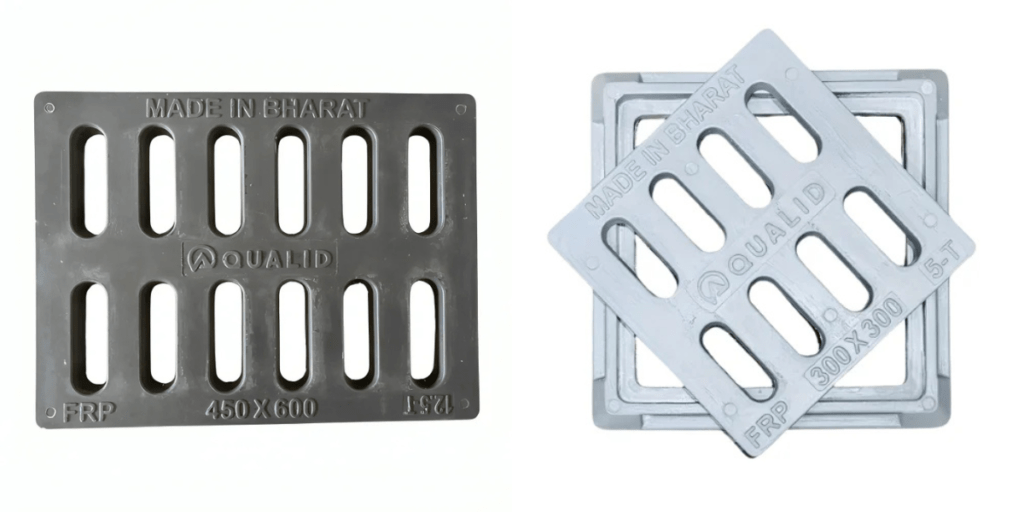

Table of Specifications FRP Gully Cover

| Specification | Details |

|---|---|

| Material | FRP Gully Cover |

| Load Capacity | Light Duty (2.5T), Medium Duty (5T), Heavy Duty (10T-35T) |

| Shape | Square, Rectangular, Round |

| Size Range | 300x300mm to 1000x1000mm |

| Color Options | Black, Grey, Green, Yellow, Customized |

| Surface Finish | Anti-Skid, Smooth |

| Resistance | Corrosion, UV, Heat, Chemicals |

| Waterproof | Yes |

| Fire Resistance | Yes (Flame retardant options available) |

| Lifespan | 25+ years |

| Standards Followed | IS 1726:1991, EN 124 |

| Country of Export | UAE, Oman, Saudi Arabia, and more |

| Delivery Time | 7-15 working days (depending on order size) |

| Customization Available | Yes (load rating, size, logo printing, etc.) |

Applications of FRP Gully Covers

- Urban Infrastructure: FRP gully covers are perfect for sidewalks, pedestrian pathways, parking lots, and residential areas in the busy cities of Dubai, Abu Dhabi, and Sharjah. Their resilience to corrosion is essential in the humid coastal environment, and their strength guarantees safety. Their adaptability in design enables them to blend in with the contemporary urban environment.

- High-load-bearing FRP gully covers are appropriate for use on roads and highways because they can endure heavy vehicle traffic and efficiently manage rainwater runoff. Because they are lightweight, they are easier to install and maintain along large road networks.

- Industrial and Commercial Areas: Heavy machinery and chemical spills are common in factories, warehouses, and commercial buildings. In these harsh conditions, FRP is a great option for gully covers due to its high strength and chemical resistance, guaranteeing lifespan and safety.

- Ports and coastal areas: Metal constructions deteriorate quickly in the hostile sea environment due to the high salt content. Because of their remarkable resistance to seawater corrosion, FRP gully covers are ideal for ports, harbors, and coastal developments.

- Airports: Reliable and sturdy infrastructure is necessary for airports. FRP gully covers provide durability and resistance to chemicals and airplane fuel, making them suitable for use in drainage systems surrounding runways and taxiways. Another safety benefit in locations with delicate electrical equipment is their non-conductive nature.

- Parks & Residential Complexes: FRP gully covers offer a visually beautiful and safe way to manage surface water in public parks and residential complexes. Their adaptability in design enables covers that complement architectural and landscaping aesthetics.

- Water treatment and desalination plants: these establishments deal with saltwater and caustic substances. Excellent resistance to these compounds is provided by FRP gully covers, guaranteeing a long service life in harsh operational situations.

Types of FRP Gully Covers

- Light Duty FRP Gully Covers: These covers are made for places with little traffic, such as parks, pedestrian zones, and apartment buildings. When heavy vehicle loads are not anticipated, they provide exceptional durability and corrosion resistance.

- Medium Duty FRP Gully Covers: Designed to endure moderate vehicle activity, these covers are appropriate for light commercial spaces, service lanes, and parking lots. They provide a harmony between weight and strength.

- Heavy Duty FRP Gully Covers: Made for places like loading docks, industrial zones, and roads where there is a lot of traffic. These coverings are incredibly strong and long-lasting, making them suitable for the harshest environments.

- Slotted FRP Gully Covers: These covers have a number of gratings or slots that let water drain effectively while keeping big debris out. They are perfect for places where rapid water runoff is needed or where floods is a problem.

- Solid Top FRP Gully Covers: These covers offer a totally sealed barrier because of their solid surface, which is devoid of any perforations. They work well in places where it’s important to keep materials out or when a continuous surface is preferred for practical or aesthetic reasons.

- The elongated trench FRP gully coverings are made to fit over linear drainage channels or trenches. To accommodate varying trench sizes and traffic needs, they come in a range of widths and load-bearing capacities.

Conclusion

In West Bengal and the UAE, the use of FRP gully covers is a major development in infrastructure management. They are an appealing substitute for conventional materials due to their superior qualities, which include high strength, corrosion resistance, lightweight design, and improved safety features. With a large selection of premium FRP gully covers designed to satisfy the unique requirements of these various markets, AQUALID is leading this shift. We are the best FRP Gully Cover Manufacturer in Rajkot.

Municipalities and infrastructure developers may guarantee long-lasting, secure, and reasonably priced drainage and utility management system solutions by selecting AQUALID, which will help create resilient and sustainable urban settings. To find out how AQUALID’s cutting-edge FRP gully covers will help your upcoming project, get in touch with them right now.